Lean Management in Services: A Complete, Modern, and Actionable Guide (AI, KPI, Practical Cases)

Why Lean Management is Crucial for Services Today

Once reserved for manufacturing, Lean Management has now become an essential performance lever for services — banking, insurance, healthcare, public administration, logistics, consulting, and IT. In these organizations, flows are often invisible: email exchanges, cases to process, online requests, and support tickets. This invisibility generates long lead times, hidden costs, and growing customer dissatisfaction.

Lean approaches applied to services make these flows visible, eliminate waste, and align teams on what truly creates value for the customer. Without heavy investments, organizations can achieve significant efficiency gains by clarifying work, simplifying decision-making circuits, and steering performance through concrete indicators.

What is Lean Applied to Services?

Lean aims to maximize value for the customer while eliminating non-value-added activities. In services, this means identifying precisely what the customer pays for — speed, reliability, simplicity, personalization — and making the invisible visible by mapping information flows and wait times. The goal is to streamline the process: fewer back-and-forth steps, less data re-entry, and fewer bottlenecks. Performance is then managed with precise and actionable KPIs, while teams engage in continuous improvement.

💡 Difference with manufacturing: you don’t transform physical parts, but rather information (contracts, quotes, files, customer tickets). Lean Services makes these flows clear, measurable, and manageable.

Tangible Benefits for a Service Organization

Customer Perspective

Response times decrease dramatically — going from several days to just 24–48 hours — and the experience becomes smoother thanks to simplified processes. Reliability improves: fewer errors, fewer follow-ups, and more trust.

Operational Perspective

Productivity increases by 10 to 30% thanks to standardized processes that reduce dependency on individuals. By eliminating unnecessary tasks, costs decrease while service quality improves.

Human Perspective

Employees are more involved in problem-solving. Clear prioritization reduces stress, while skill development enhances individual potential.

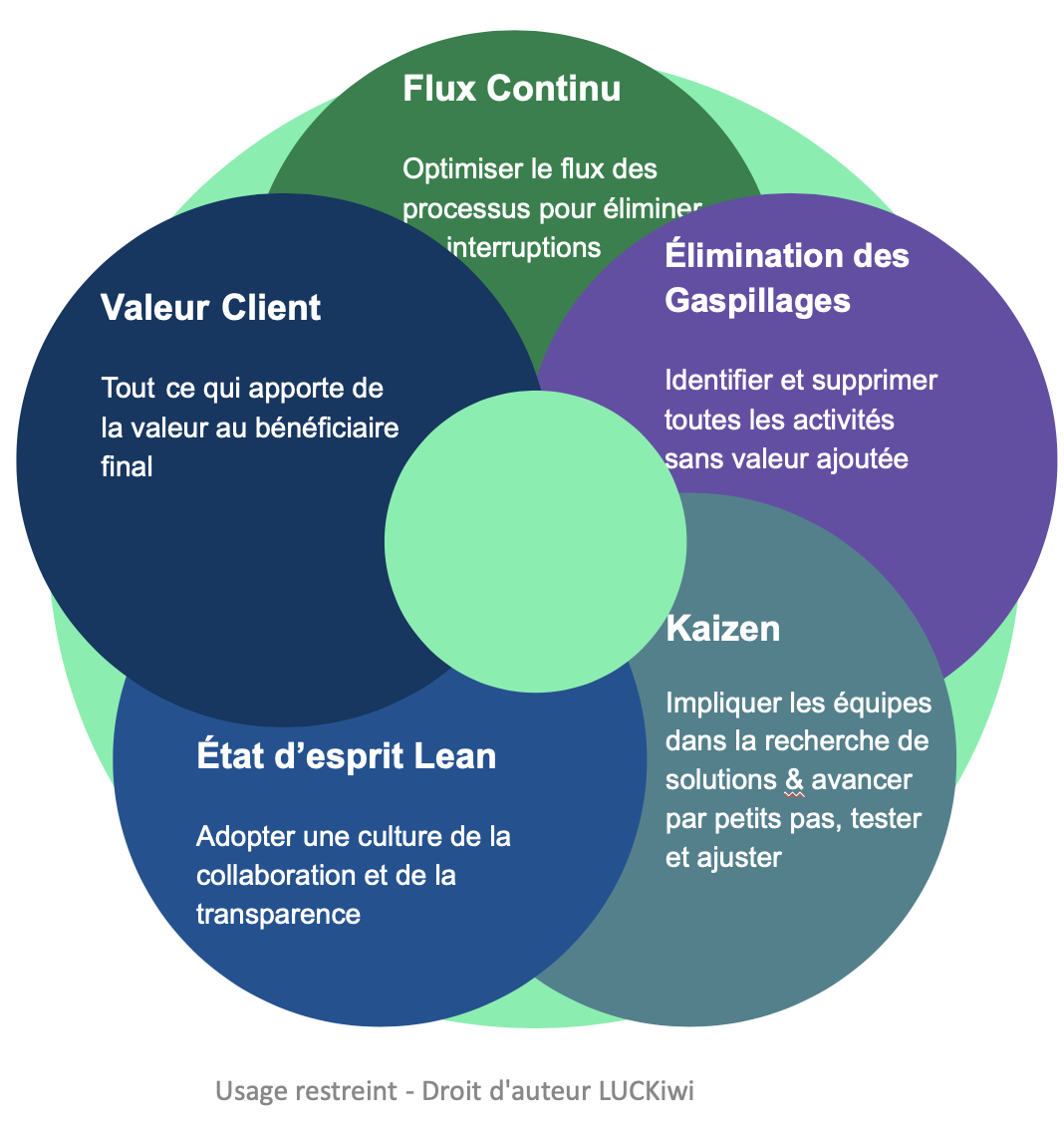

The 5 Lean Steps Adapted to Services (Enhanced by Digital)

1) Identify Value (Voice of Customer & Voice of Stakeholders)

Start by understanding what the customer really expects: speed, transparency, and simplicity. Balance these expectations with internal constraints — regulations, risks, resources — to make informed decisions. AI tools can analyze emails and customer verbatims to identify key pain points and prioritize high-impact improvement projects.

2) Map the Value Stream (Value Stream Mapping for Services)

Visualize the entire journey, from the initial request to delivery. Identify dead time, duplicate data entry, queues, and validation loops. Tools like process mining or visual collaboration platforms make the workflow visible and shared.

3) Create a Continuous Flow

Reduce queues by limiting work in progress (WIP). Eliminate process breaks by defining single entry points, centralized channels, and clear processing rules. Repetitive tasks can be automated through RPA or integrated SaaS tools.

4) Implement a Pull System

Work based on actual demand rather than forecasts. Classify requests by criticality and set clear SLAs to smooth the workload and ensure reliable turnaround times.

5) Strive for Perfection Through Continuous Improvement

Structure activities with short rituals (AIC) and visible KPIs for the team — lead time, first response rate, backlog. Experiment, measure, adjust, and standardize improvements using the PDCA cycle to achieve lasting results.

The 7 Types of Waste in Services (TIMWOOD) + the 8th

Transport: When documents are manually transferred between departments, delays increase. A unified digital circuit eliminates friction and secures handovers.

Inventory (work in waiting): Backlog of cases in back-office immobilizes value. Limiting WIP and daily sorting accelerates flow.

Motion (unnecessary movements): Collecting physical signatures wastes time. E-signatures make the process faster and more reliable.

Waiting: A validation blocked by an absent manager creates bottlenecks. Clear delegation and automated workflows prevent immobilization.

Over-Processing: Re-entering the same data into multiple systems multiplies errors. Integration through APIs eliminates redundancy.

Over-Production: Generating reports that are never used consumes resources without value. Data governance ensures production aligns with actual needs.

Defects: Errors in quotes lead to costly rework. Smart forms with built-in controls help reduce mistakes.

8th Waste — Underutilization of Talent:Lack of engagement and autonomy hinders improvement. A participatory Kaizen system, role rotations, and training unleash innovation.

Key KPIs to Measure Lean Services ROI

Lead Time (end-to-end): Time from initial request to final delivery. Target a 20-40% reduction for predictable service.

First Contact Resolution Rate: Percentage of requests resolved without follow-up or correction. Aim for a 15-25 point increase to improve satisfaction.

Productivity: Number of requests processed per FTE (Full-Time Equivalent). Expect a 10-30% increase through standardization and workload balancing.

Quality: Error or rework rate. A minimum 30% reduction is a solid milestone — aiming for 40-50% is even better as maturity grows.

Customer Satisfaction: Measurement of perceived experience. A 10-point increase shows key pain points have been addressed.

Employee Engagement: Number of implemented improvement ideas. Seek at least a 20% increase to anchor the improvement culture.

💡 About the “+” for quality: a –30% target is the minimum expected reduction. The “+” means going beyond this goal is desirable, such as achieving –40% or –50%.

Practical Cases Across Various Sectors

Insurance — Claims Management

Long delays and repetitive data entry between insurer and experts harmed the customer experience. By deploying a digital workflow, VSM, and eliminating redundant steps, processing time dropped by 40% and satisfaction increased by 12 points.

Public Administration — Citizen Case Management

Waiting times and administrative complexity fueled backlog. A single access point, simplified forms, and a digital Kanban reduced backlog by 35% and halved average processing time.

E-commerce Logistics — Returns Customer Service

Poor traceability caused multiple customer follow-ups. A pull system, automated notifications, and visible KPIs boosted the first contact resolution rate by 20 points while cutting service costs by 25%.

Consulting Firm — Project Management

Inefficiencies between consultants and support functions limited value delivery. A project VSM, standardized deliverables, and AIC rituals improved productivity by 18% and internal satisfaction by 15 points.

How to Deploy Lean Services in 90 Days

Days 0–30 — Diagnosis and Visibility:Map the key process using VSM and measure the starting point (lead time, first contact resolution rate, backlog). Initial clarity sets the right priorities.

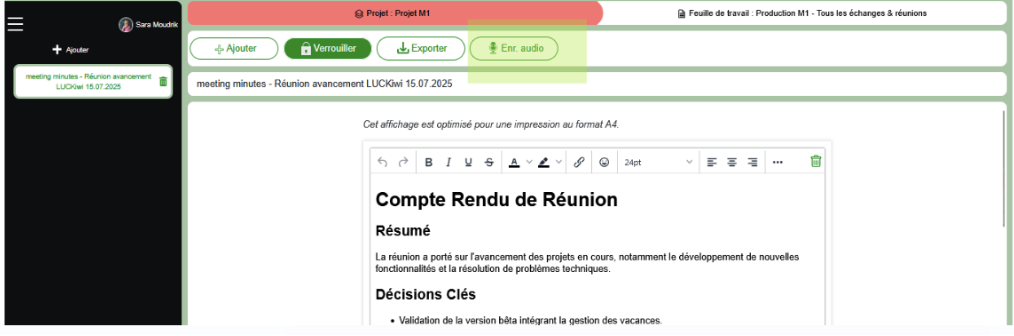

Days 31–60 — Stabilization:Define clear standards (procedures, checklists), visualize work, and limit WIP with a Kanban system. You can start easily with the free version of LUCKiwi to test the method with your team and apply WIP limits concretely. Automating repetitive tasks will further stabilize the process.

Days 61–90 — Pull and Continuous Improvement:Set SLAs by request category, run short rituals around KPIs, and engage the team in the improvement loop to sustain gains.

Lean and Digitalization: A Winning Duo

AI automatically categorizes tickets and identifies bottlenecks. RPA automates repetitive tasks like data entry and reconciliation. Real-time BI enables dynamic KPI dashboards. E-signatures and APIs eliminate process breaks. Key rule: first stabilize processes with Lean, then digitize, and finally amplify with AI.

Practical Checklist to Get Started

Make sure you have a sponsor and clear objectives, a target process defined with the field team, and a completed VSM. Measure your baseline KPIs, create standards and checklists, and implement a digital Kanban with WIP limits. Automations and RPA should only come after stabilization. Finally, run AIC rituals (e.g., daily 5–15 minute meetings) and track KPIs in a real-time BI dashboard.

Conclusion

Lean Management applied to services is not just a method — it’s a cultural shift. By combining process simplicity, smart digitalization, and rigorous KPI-driven management, you can transform your services into a sustainable competitive advantage.

Take action today: book a quick diagnostic session to identify your top three bottlenecks and build a 90-day action plan. Try our AI solution to automatically generate Lean reports in one click and free up your team's time — Free Trial.

Article written by Sara MOUDRIK HORN